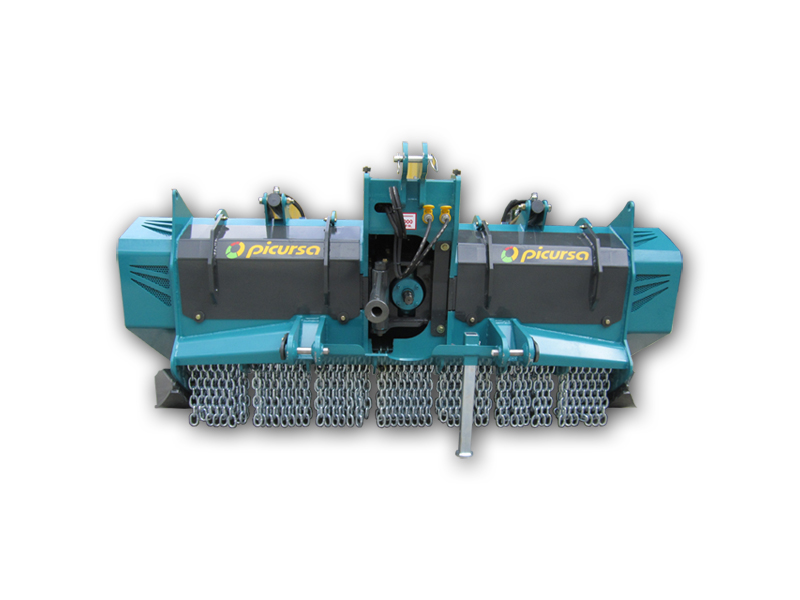

Forestry mulcher Rotor 450 double PTO shaft

The Rotor 450 Mulcher is specially designed to shred pruned branches, small trees and debris from tree-felling and scrub clearance.

Features:

Robustness

Innovation

Flexibility

Durability

Forestry mulcher Rotor 450 double PTO shaft description:

The Rotor 450 Mulcher is specially designed to shred pruned branches, small trees and debris from tree-felling and scrub clearance. This mulcher is designed for use with tractors from 160 to 300 HP. It is equipped with a rotor containing four rows of swinging hammers that are concealed in the interior of the rotor to protect them from strong impacts from tree trunks or stones, lengthening the useful life of the hammers. The special positioning of the hammers on the rotor produces very fine shredding and the shredded material is evenly spread over the terrain. Models wider than 2 metres are equipped with a PTO (power take-off) shaft on both sides of the rotor. Skid runners for height adjustment. Hydraulic or manually controlled hinged hood. Very solid and sturdily built.

Forestry mulcher Rotor 450 double PTO shaft features:

- SWING HAMMER ROTOR WITH SPECIAL DISTRIBUTION AND LOW POWER ABSORPTION

- ROTOR Ø 600 mm.

- ROTOR STRUCTURE MADE OF ANTI-WEAR MATERIAL AND Ø 480 mm.

- AXLE DIAMETER Ø 90 mm.

- METAL CHASSIS WITH HIGH ELASTIC LIMIT

- INTERCHANGEABLE TWIN CHASSIS MADE OF ANTI-WEAR MATERIAL

- STEEL BEARING SHELLS

- ROTOR BEARINGS WITH DOUBLE ROW OF ROLLERS

- V-BETL WITH KEVLAR FIBRE

- F-127 HAMMER DIBBERS

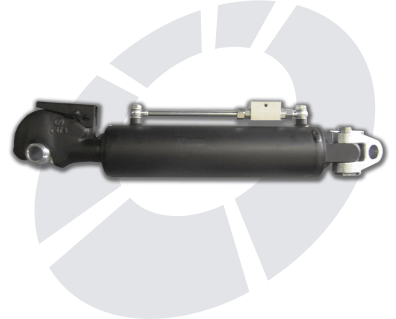

- HYDRAULIC CYLINDRES FOR THE HINGED HOOD

- GROUP WITH FREE WHEEL

- TRANSMISSION INCLUDED

Forestry mulcher Rotor 450 double PTO shaft models:

| Working width | Overall width | Weight Kg. | Hammers | Belts | HP (indicative) | R.P.M. | Shaft |

|---|---|---|---|---|---|---|---|

| 2000-2EF | 2380 | 2725 | 30 | 8 | 160-240 | 1000 | 1″ 3/4 Z-6 |

| 2170-2EF | 2550 | 2955 | 32 | 8 | 200-280 | 1000 | 1″ 3/4 Z-6 |

| 2400-2EF | 2780 | 3270 | 36 | 8 | 220-300 | 1000 | 1″ 3/4 Z-6 |

Forestry mulcher Rotor 450 double PTO shaft accesories:

Mechanical adjustment bars

Hydraulic adjustment bars

Hydraulic extender bars

Grated fine shredding

Third hydraulic point

Deutsch

Deutsch Español

Español Français

Français